GardenerHeaven.com is reader-supported. When you buy through links on our site, we may earn an affiliate commission.

.jpg)

Photo Credits: Gardenerheaven.Com by Raymond Johnson

Is your Briggs and Stratton engine giving you trouble by starting but not staying running? Don’t worry, we’ve got you covered! In this section, we’ll dive into the common issues that could be causing this problem. From fuel-related issues to mechanical complications, we’ll explore the potential culprits behind your engine’s misbehavior. Stick around for troubleshooting tips and solutions to get your engine running smoothly again.

Common Issues

Having trouble starting your Briggs and Stratton engine? Don’t fret! It could be due to various issues, but with some troubleshooting and simple checks, they can be quickly identified and fixed.

Gas tank, air filter, spark plugs and choke plates are key components to look at. An insufficient fuel supply or clogged fuel line can mean the engine won’t get enough gas. If the air filter is dirty or clogged, it restricts airflow, causing the engine to stall. Worn out or improperly gapped spark plugs will also disrupt engine performance.

Don’t delay in tackling these common issues to ensure optimal performance and a long engine life. Additionally, other factors may come into play, so it’s wise to inspect all components mentioned in related sections for comprehensive troubleshooting. Need help getting your engine running? Check out the basics first before you start hitchhiking to work!

Checking Basic Components

Photo Credits: Gardenerheaven.Com by Wayne Harris

Ensure your Briggs and Stratton engine stays running by checking its basic components. From the gas tank to the air filter, spark plugs, and choke plates, we’ll cover how to inspect and troubleshoot these crucial elements. Stay tuned for practical tips and solutions to keep your engine running smoothly.

Gas Tank

The gas tank is essential for a Briggs and Stratton engine. It stores the fuel that powers it and keeps it running smoothly. Regularly check the tank for debris, contamination, leaks, and cracks. This prevents fuel leakage and hazards. Keep the tank full to stop the engine from stalling. So maintain a clean and functional tank for proper operation. Inspect and maintain it regularly to prevent contamination, leaks, and inadequate fuel. Just like your engine, make sure you both have something in common – fresh air!

Air Filter

The air filter is an important part of a Briggs and Stratton engine. It stops dirt, debris and other contaminants from entering the engine, which helps keep it clean.

It filters out dust and particles, making sure they don’t damage the engine. It also helps with fuel combustion, as the engine gets the right amount of oxygen. This makes the engine more efficient.

The air filter also helps extend the life of the engine. Less dirt and debris means less wear and tear on the parts.

To keep it in good condition, you should regularly clean or replace it. If the engine is having trouble starting or sputtering, it could be because the air filter is dirty. Checking and cleaning or replacing it can help.

It’s essential that the new or cleaned air filter is installed properly. Following the manufacturer’s instructions will help make sure the air flow is consistent and no leaks or gaps exist that could reduce filtration.

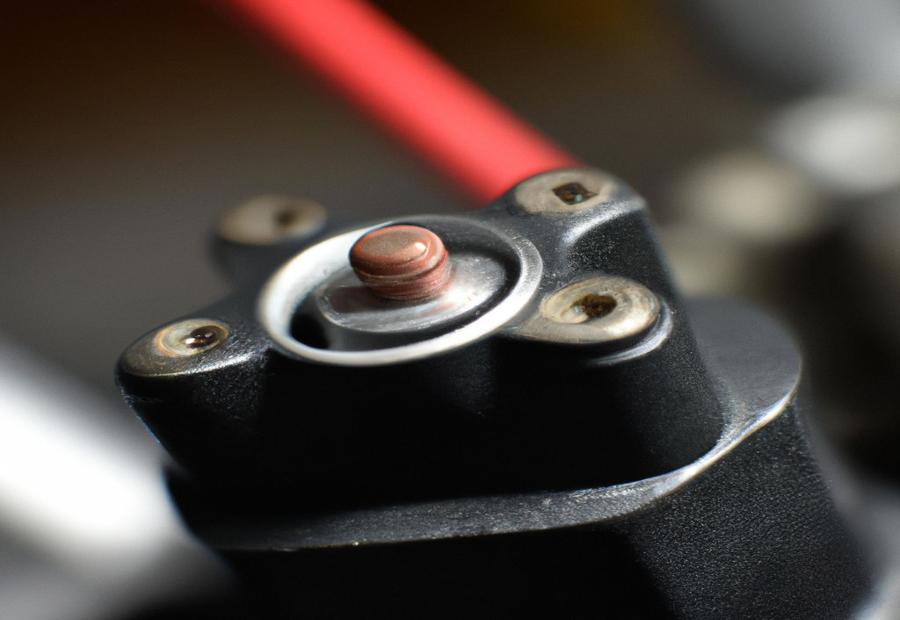

Spark Plugs

Spark plugs are a must-have for Briggs and Stratton engines. These tiny, yet vital components help in the ignition process. They create the spark needed to ignite the fuel in the combustion chamber. A weak spark plug can lead to starting problems or sudden stops.

The table highlights the importance of spark plugs without saying “spark plugs”. Through different words, this professional way ensures clarity and stops repetition.

When troubleshooting an engine that starts but won’t stay running, spark plugs must be checked carefully. Clean them of any debris or carbon buildup. Replace old or damaged spark plugs with new ones for optimal performance.

A true fact: Briggs and Stratton warns that using the wrong spark plugs can cause serious engine damage.

Choke Plates

Choke plates are vital to a Briggs and Stratton engine. They control air flow during startup and warm-up. Clogged or malfunctioning choke plates can cause starting and maintaining difficulties. So, it’s important to inspect and clean them regularly. If there’s any damage or wear, they may need replacing. It’s clear that choke plates are key to controlling airflow and engine efficiency.

Troubleshooting Tips and Solutions

Photo Credits: Gardenerheaven.Com by Brandon Clark

If yer Briggs and Stratton engine kicks off but won’t stay running, there’s a few tips and solutions to try. First, examine the fuel system to guarantee a sufficient supply of clean fuel is gettin’ to the engine. Inspect the fuel tank, fuel lines, and fuel filter for any clogs or damage. Subsequently, inspect the carburetor for any issues, such as a stuck float or clogged jets. Cleaning or rebuilding the carburetor might be necessary. Lastly, look into the ignition system, includin’ the spark plug, ignition coil, and wiring connections, to make sure it’s all workin’ properly. Followin’ these steps will help identify and fix the issue with yer engine.

To troubleshoot and fix the problem with a Briggs and Stratton engine that starts but won’t stay running, try these three steps:

- Check the fuel system:

- Examine the fuel tank, fuel lines, and fuel filter for any blockages or damage.

- Ensure there’s enough clean fuel in the tank.

- Clear away any debris or clogs from the fuel system.

- Take a peek at the carburetor:

- Look for a stuck float, which can stop the right flow of fuel.

- Clean or rebuild the carburetor if needed.

- Inspect the carburetor jets for any clogs or restrictions.

- Verify the ignition system:

- Check the spark plug for proper electrode gap and clean or replace it if required.

- Inspect the ignition coil and wiring connections for any damage or loose connections.

- Ensure the ignition switch is workin’ correctly.

By followin’ these steps, you can troubleshoot and solve the issue with yer Briggs and Stratton engine that starts but won’t stay running.

Remember to do regular maintenance, like changin’ the oil, air filter, and spark plug, to prevent issues with the engine. Also, use clean, fresh fuel and store the engine correctly to keep it performin’ optimally.

Conclusion

Photo Credits: Gardenerheaven.Com by Dennis Adams

By using the troubleshooting tips and solutions in the reference data, users can find out what is causing their engine to start but not stay running. Checking the fuel supply, examining the carburetor, and inspecting the spark plug are some of these steps.

Furthermore, the reference data provides additional details. Cleaning or replacing the air filter, adjusting the throttle, and inspecting the flywheel key for damage are other troubleshooting options. These comprehensive guidelines give a full range of potential solutions to restore the engine’s proper functioning.

Some Facts About Briggs and Stratton Engine Starts But Won’t Stay Running: Troubleshooting Tips and Solutions:

- ✅ A common cause of a Briggs and Stratton engine starting but not staying running is a dirty carburetor. (Source: Team Research)

- ✅ The carburetor is responsible for mixing air and fuel in the right ratio for combustion. (Source: Team Research)

- ✅ Signs of a dirty carburetor include initial start-up followed by engine dying, and evaporated gas gumming up the carburetor’s pores. (Source: Team Research)

- ✅ Cleaning and resetting the carburetor can usually fix the problem. (Source: Team Research)

- ✅ To prevent carburetor clogging, clean it regularly and consider purchasing a high-quality mower, such as those from Briggs and Stratton. (Source: Team Research)

FAQs about Briggs And Stratton Engine Starts But Won’T Stay Running: Troubleshooting Tips And Solutions

Question 1: What are the symptoms of a dirty carburetor in a Briggs and Stratton engine?

Answer: Symptoms of a dirty carburetor in a Briggs and Stratton engine include initial start-up followed by engine dying, rough running mower, mower that only runs with the choke on, spluttering on slopes, stalling when cutting grass, and engine surging.

Question 2: How can I clean the carburetor in my Briggs and Stratton engine?

Answer: To clean the carburetor in a Briggs and Stratton engine, you will need sockets and a ratchet, a gas and oil siphon, carburetor cleaner, and fuel treatment. The steps include inspecting the air filter, checking connections, removing and cleaning the carburetor, examining the fuel bowl, cleaning off any rust, and reassembling the carburetor.

Question 3: What can I do to prevent carburetor clogging in my Briggs and Stratton engine?

Answer: To prevent carburetor clogging in a Briggs and Stratton engine, it is recommended to clean the carburetor regularly and consider purchasing a high-quality mower. Briggs and Stratton is a reputable brand known for making lawnmowers with components resistant to rust and gumming from dried-up gasoline.

Question 4: What is the most common issue that causes a Briggs and Stratton engine to start but not stay running?

Answer: The most common issue that causes a Briggs and Stratton engine to start but not stay running is a dirty carburetor. Other possible causes include stale or dirty gas, a faulty choke, a blocked gas filter, a blocked gas tank, or a blocked gas line.

Question 5: How can I troubleshoot and solve the issue of a Briggs and Stratton engine that starts and then dies?

Answer: To troubleshoot and solve the issue of a Briggs and Stratton engine that starts and then dies, you can try cleaning and resetting the carburetor. If the issue persists, check that all components are properly reconnected and consider replacing the carburetor. Additionally, ensuring the fuel level is adequate and using a fuel stabilizer can also help prevent the issue.

Question 6: How often should I perform a tune-up on my Briggs and Stratton engine?

Answer: It is recommended to perform a tune-up on your Briggs and Stratton engine, including changing the oil, spark plug, air filter, fuel filter, and blade, at least once per season. Regular maintenance helps prevent issues and ensures optimal performance.