GardenerHeaven.com is reader-supported. When you buy through links on our site, we may earn an affiliate commission.

Throttle linkage plays a crucial role in the performance of a Kohler carburetor. This section will explore the definition and function of throttle linkage and the critical components involved. Understanding how throttle linkage works and how to adjust it properly is essential for optimizing engine performance. So, let’s dive in to learn more about this vital aspect of Kohler carburetors.

Definition and Function of Throttle Linkage

Photo Credits: Gardenerheaven.Com by Elijah Anderson

Throttle linkage is essential for engine operation, specifically the carburetor. Its main job is to open and close the throttle valve so that air-fuel mix enters the combustion chamber. This ensures the engine gets the right fuel and air for optimal performance.

Components that make up the throttle linkage include the cable, lever, shaft, and spring. The cable transmits motion from the accelerator pedal to the lever, which rotates the shaft. The shaft’s rotation adjusts the throttle valve, controlling airflow into the engine. The spring provides consistent tension in the system.

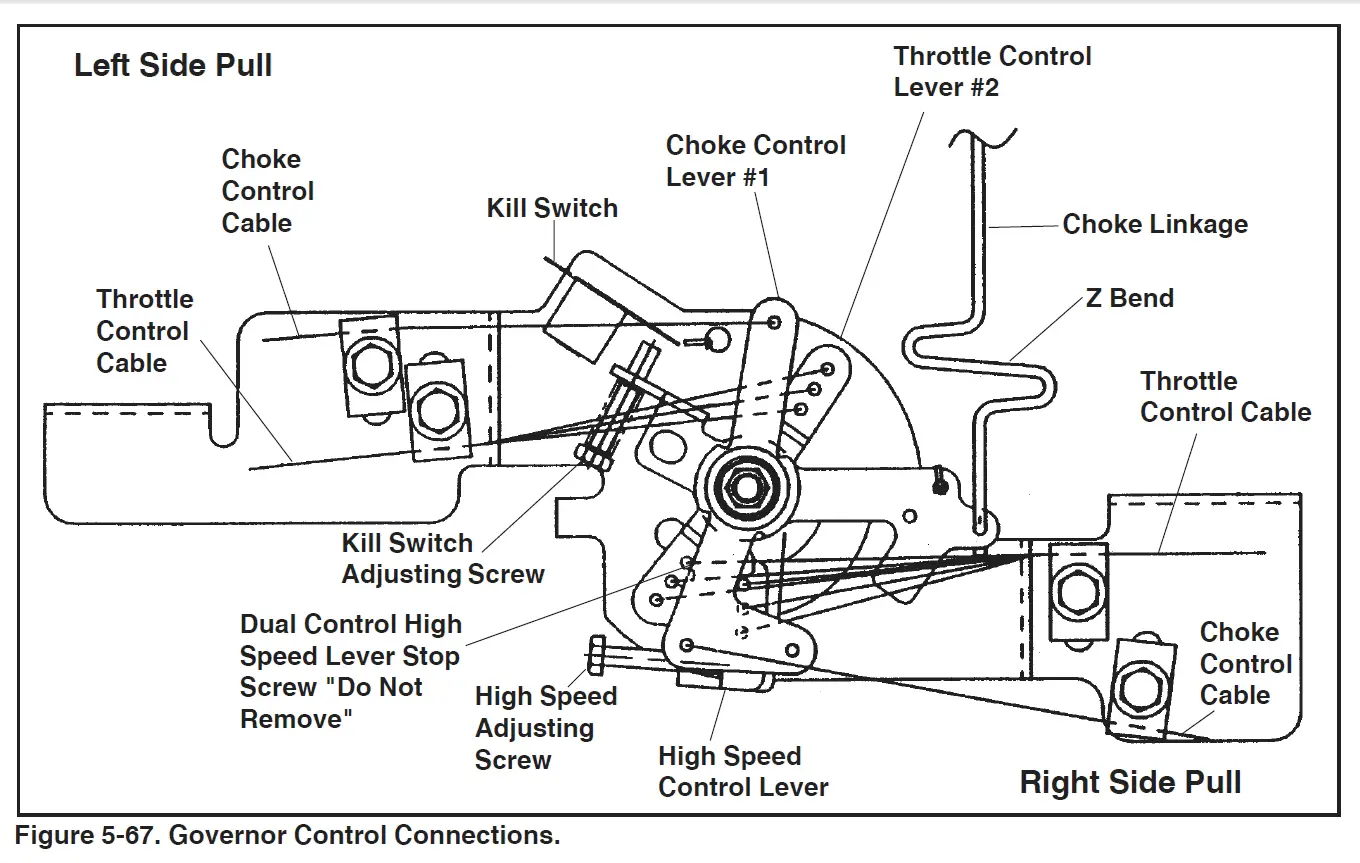

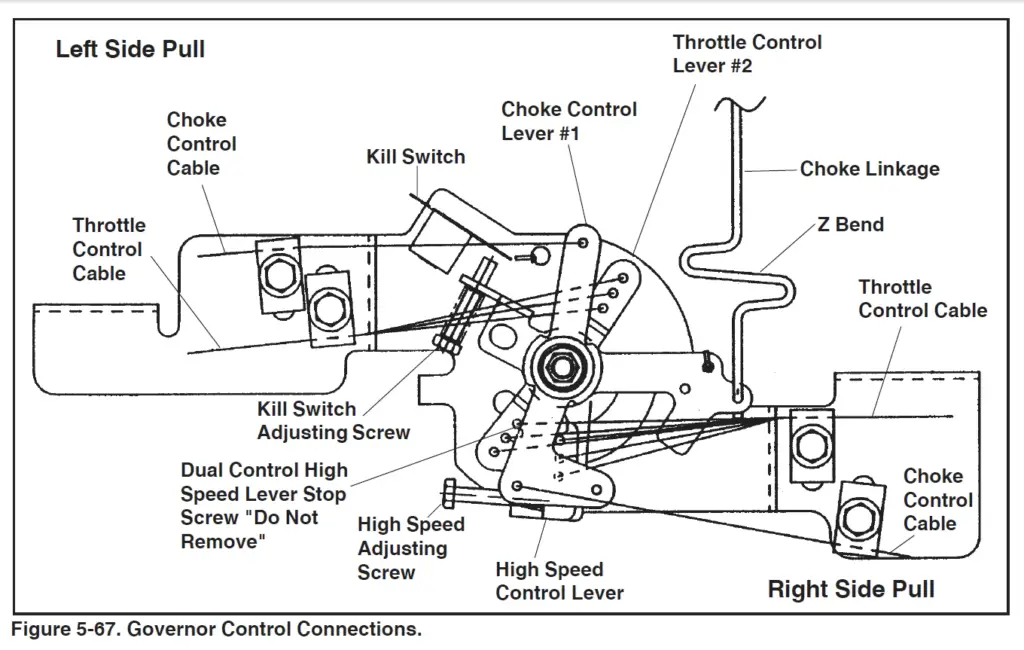

A carburetor linkage diagram is critical to understanding how these pieces work together. It shows how each part links and affects motion. By studying this diagram, technicians can see misaligned or damaged parts and diagnose problems with throttle response.

When adjusting throttle linkage, follow a step-by-step process. First, identify the correct setup for your engine model. Then, inspect and clean all components involved. Adjustments come next, using manufacturer guidelines or specs. Finally, test for optimal functionality and responsiveness.

Troubleshooting is needed when malfunctions occur. Sticking throttle problems often come from worn or damaged components in the linkage. Erratic throttle response could be from a loose or improperly adjusted connection or fuel flow issues. A malfunctioning throttle position sensor or faulty fuel delivery might cause inconsistent engine RPM.

Ready to understand the pieces that make your engine go vroom?

Components of Throttle Linkage

Throttle Linkage is a critical component in an engine’s operation. It connects the throttle pedal or lever to the carburetor, enabling airflow and fuel intake regulation. We can refer to a carburetor linkage diagram to gain a fuller understanding. This diagram provides info on all the parts of the throttle linkage system, making it simpler to identify and understand their functions. It visually demonstrates the connections and arrangements of components, being a helpful tool for troubleshooting and adjusting the throttle system.

Let us take a look at some of the critical components found in a typical throttle linkage setup:

- Throttle Pedal/Lever: This is the part operated by the driver or user, either through a pedal or a lever. It controls the opening and closing of the throttle valve.

- Linkages: Rods, cables, or bell cranks transmit motion from the throttle pedal/lever to other system parts. These linkages sync input from the driver with the movement of the throttle valve.

- Throttle Shaft: This shaft controls airflow by opening or closing the throttle valve inside the carburetor.

- Return Springs: Return springs bring back the accelerator pedal/lever and throttle valve to their idle positions when no force is applied. These springs ensure smooth operation and no unintended acceleration.

- Pivot Points: Pivot points provide rotational movement for different components within the linkage system. They allow for proper articulation and smooth functioning of linkages when transmitting motion.

With knowledge of these components and their functions within the throttle linkage system, one can diagnose issues related to sticking throttles, erratic throttle response, or inconsistent engine RPM. Proper adjustment and maintenance of the throttle linkage are essential for an engine’s optimal performance and durability. Make your engine scream like a rockstar on caffeine!

Understanding Throttle Linkage

Photo Credits: Gardenerheaven.Com by Frank Mitchell

Throttle linkage plays a crucial role in the functioning of a Kohler carburetor. This section will comprehensively understand throttle linkage, including its definition, function, and critical components. By unraveling the mechanics behind throttle linkage, readers will be equipped with valuable knowledge for adjusting and optimizing their carburetors. Let’s dive into the intricacies of this vital component and unlock the potential for smoother engine performance.

Definition and Function of Throttle Linkage

Throttle linkage is vital for connecting the accelerator pedal to the carburetor. It enables control of the engine’s speed and power output. This process has several components that work together. They transfer the movement of the pedal to the carburetor’s throttle plate.

The linkage translates the driver’s accelerator pedal input into an opening or closing of the throttle plate. This manages the air and fuel going into the engine, thus controlling its speed and power. The main components include the accelerator cable, throttle body, lever arm, return spring, etc.

To use the throttle linkage system optimally, it is essential to understand a carburetor linkage diagram. This provides an overview of how the components are connected. Identifying issues and making adjustments is easier with this. Studying each part of the diagram is necessary. Also, inspect/clean them.

Adjusting the throttle linkage requires a step-by-step approach. First, identify the setup specific to your vehicle model. Second, inspect and clean all components. Third, adjust the tension and alignment of linkages. Fourth, test the throttle response.

Inspecting and maintaining the throttle linkage system is necessary to prevent potential problems. Failing to do so can cause poor performance or safety hazards while driving. Understand your vehicle’s setup and perform routine inspections and maintenance.

Let’s dive into the exciting world of throttle linkage components! Carburetor diagrams await!

Importance of Carburetor Linkage Diagram

Understanding the importance of the carburetor linkage diagram is critical to ensuring the optimal performance of your Kohler engine. In this section, we’ll explore an overview of the carburetor linkage diagram and delve into the essential components that make up this diagram. By understanding how these components work together, you’ll gain valuable insights into properly adjusting and maintaining your throttle linkage for optimal engine functionality.

Overview of Carburetor Linkage Diagram

The Carburetor Linkage Diagram gives an overview of the parts and their connections in the throttle system. It shows how they work together to control throttle response and engine performance.

The Diagram has three columns: “Component Name,” “Function,” and “Connection.”

The Component Name column lists the parts of the linkage system, like the throttle lever, accelerator pump rod, and return spring.

The Function column explains the purpose of each part in regulating fuel and air mixture delivery to the engine.

The Connection column shows the links between the components, demonstrating their positions and relationships.

Unique details can be seen in this diagram. These show how changing certain connections can affect engine RPM and throttle response or prevent issues like sticking throttle or erratic behavior.

Mechanics and technicians can use this diagram to find problems in the carburetor linkage system and take necessary actions.

Knowledge is power. Knowing the throttle linkage diagram components will help you troubleshoot!

Understanding the Diagram Components

Grasping the diagram’s elements is vital for understanding the complexities of a carburetor’s throttle linkage. The diagram visualizes the pieces included, allowing users to distinguish and comprehend their individual roles and associations.

We can make a table to display the throttle linkage parts using the given data. The table will have columns that show these components, providing users with a comprehensible and well-organized overview. By displaying this data visually, folks can conveniently look up and comprehend the various parts engaged in the throttle linkage system.

Apart from the components mentioned above, other unique details deserve attention. These details go further into some aspects of the throttle linkage system, offering supplementary knowledge and understanding. By expanding our knowledge beyond what was previously explained, we can guarantee a thorough comprehension of how each component adds to the general performance of the system.

Time to show off your throttle savvy with these adjustment tips!

Adjustment Tips for Throttle Linkage

In this section, we’ll provide you with valuable adjustment tips for throttle linkage in your Kohler carburetor. We’ve covered you, from identifying the correct linkage setup to testing the throttle response. With these essential tips, you’ll better understand how to fine-tune your throttle linkage for optimal performance. Let’s dive in and get your engine running smoothly!

Step 1: Identifying the Correct Linkage Setup

Correct linkage setup is essential when dealing with throttle linkage. The system will run properly and effectively by ensuring the proper setup. Reference info gives a deep understanding of the components of throttle linkage, aiding in recognizing the correct setup. Here is a 4-step guide to doing it:

- Step 1: Look into the parts: Examine the throttle system’s parts, like the carburetor linkage diagram. This will give you an idea of how everything is connected and help you figure out the proper setup.

- Step 2: Follow manufacturer’s rules: Check for any particular instructions or guidelines the manufacturer gives regarding the correct setup for your vehicle or equipment. Manufacturers often give detailed diagrams or directions to aid in recognizing the correct configuration.

- Step 3: Compare with reference: Check reliable sources like service manuals or online resources with info on throttle linkages and their setups. Compare these references with your system to ensure you have the correct configuration.

- Step 4: Ask for help if needed: If you are unsure about the setup, getting assistance from an experienced mechanic or technician who knows about this area is best. They can provide advice and make sure you have the correct setup implemented.

It is vital to identify the correct linkage setup since it affects engine operation and the performance of the throttle system. Taking the time to do it correctly will lead to good results and avoid issues. According to Kohler, correctly identifying throttle linkage setups is vital to preserving engine efficiency and preventing damage from incorrect setups.

Step 2: Inspecting and Cleaning the Linkage Components

Inspecting and cleaning the linkage components is essential when adjusting the throttle linkage. Examine each component carefully, looking for dirt, grease, corrosion, or loose/missing bolts. Clean all components using a suitable cleaning agent or solvent, and lubricate any movable parts with oil. Reassemble the components carefully and securely.

Follow this guide to maintain the linkage components optimally. Exercise caution during the process to avoid damage. Paying attention to these small details can prevent future issues like sticking throttle or inconsistent engine RPMs!

Step 3: Adjusting the Throttle Linkage

- Spot the Correct Setup – Locate the correct setup for your engine by referring to the manufacturer’s instructions or a carburetor linkage diagram. Knowing the accurate setup is vital for successful adjustments.

- Check & Clean Components – Check the throttle linkage components for wear or damage. Clean off any dirt that could affect their movement.

- Adjust the Linkage – Carefully loosen locking screws or nuts and adjust the linkage in small increments until you get the desired response. Securely tighten the screws and nuts afterward.

- Test the Response – Fire up the engine and check how it responds to changes in throttle input. No sudden surges or delays should occur. Make further adjustments until the throttle response is smooth and consistent if needed.

- Time to test the Throttle Response – buckle up for the ultimate thrill ride!

Step 4: Testing the Throttle Response

Testing a throttle’s response is essential for its proper function. Follow the steps to examine its responsiveness accurately.

- Identify the correct linkage setup. This ensures testing is done with the right parts.

- Thoroughly inspect and clean the components of the throttle linkage. Dirt and debris could hinder smooth movement.

- Adjust the linkage to prevent slack or tightness.

- Test the response using controlled movements. Observe any irregularities or abnormal behavior.

- Test under different engine conditions and speeds. This will provide a full evaluation.

Step 4 focuses on thorough assessments of performance.

By following these steps and paying attention to any issues, technicians can diagnose and address problems with sticking throttles, erratic responses, or inconsistent engine RPMs.

Troubleshooting Common Issues

Mastering the art of carburetor linkage adjustment is crucial for troubleshooting common issues in your Kohler engine. This section will address three major concerns: sticking throttle, erratic throttle response, and inconsistent engine RPM. Unravel the secrets behind these problems and discover practical tips to alleviate them, ensuring optimal performance and a smooth-running engine. Say goodbye to frustrating engine hiccups with our expert guidance and adjustment techniques.

Sticking Throttle

The throttle linkage is a vital part of a carburetor’s functioning. It controls the opening and closing of the throttle valve, which affects the air and fuel flow into the combustion chamber. Problematic throttle movement can lead to issues with engine performance and responsiveness.

To sort this out, do these three things:

- Look for Blockages: Check if dirt, debris, or other hindrances are causing the throttle to stick. Clean or take away any blockages with a suitable cleaner or solvent.

- Grease the Moving Parts: Lubricate all the moving parts of the throttle linkage, including pivot points and joints. This will reduce friction and provide smoother operation.

- Set Right Tension and Alignment: Make sure the tension in the throttle linkage is adjusted according to manufacturer guidelines. Also, confirm that all components are in correct alignment and secured. Make any necessary changes to ensure proper operation.

Following these steps, you can run the throttle smoothly and get your carburetor back on track. Remember, if these steps don’t work or you’re unsure how to do them, seek help from a professional mechanic or refer to your engine model’s manufacturer guidelines.

Erratic Throttle Response

Erratic throttle response? That’s when the engine’s acceleration doesn’t match the throttle’s movement. It can cause delayed or inconsistent power, making it tricky to control the vehicle’s speed.

Crucial throttle linkage. It lets air and fuel flow into the engine, which affects performance. Dirt, worn components, or improper adjustment can lead to an erratic throttle response.

Sticking throttle? That’s when the throttle valve doesn’t return to the closed position. Dirt in the throttle body and worn pivot points in the linkage can be the culprits.

TPS malfunction? That’s when the throttle position sensor sends wrong signals to the engine control unit. Faulty or incorrectly adjusted TPS leads to inaccurate readings and erratic throttle response.

Inconsistent engine RPM can also cause an erratic throttle response. Fuel delivery and ignition timing – can be factors.

Time to troubleshoot. Inspect and clean all components, and adjust the throttle linkage properly. That’s the way to ensure smooth and precise operation.

Inconsistent Engine RPM

The throttle linkage controls the air and fuel mixture entering the engine. It includes the throttle cable, lever, and connecting rods. When the driver hits the accelerator, the throttle linkage turns this into opening or closing the carburetor’s throttle valve. This affects engine RPM.

Refer to a carburetor linkage diagram to detect and fix engine RPM problems. This shows how all the components are connected and their exact positions. This can uncover any misalignment or broken parts causing inconsistent engine RPM.

Besides studying the diagram, some tips can address engine RPM problems. Firstly, figure out the correct linkage setup for your model. Cleaning all parts thoroughly is also essential for smooth movement. Adjusting the linkage per manufacturer instructions can improve engine performance. Lastly, testing the throttle after making adjustments lets you know if more changes are needed.

You can sort out inconsistent engine RPM by following these steps and fixing any issues in the throttle linkage. Looking after these components and inspecting them regularly can stop future problems.

Conclusion

Photo Credits: Gardenerheaven.Com by Mark Taylor

Throttle linkage in a Kohler carburetor is essential for controlling the engine’s speed. Precise adjustment prevents fuel wastage and ensures optimal performance. Refer to the Kohler carburetor diagram to understand and adjust the throttle linkage. It shows the connection between the throttle lever and the throttle plate.

Adjusting the lever’s position regulates the amount of air and fuel entering the engine. The linkage consists of rods, springs, and pivots that work together. The following tips help to achieve desired results.

- Firstly, ensure the throttle lever is correctly aligned with the idle-speed screw and the wide-open throttle stop. Check for wear or damage in the linkage components and replace them if needed. Lubricate the moving parts for smooth operation. Listen to the engine’s sounds and observe any changes in performance.

- A properly adjusted throttle linkage should sound smooth at idle, accelerate crisply, and respond consistently. Consult the manufacturer’s guidelines for the specific Kohler carburetor model. Following these guidelines adds accuracy to the adjustment process.

In summary, understanding and adjusting the throttle linkage in a Kohler carburetor is essential for efficient engine operation. Refer to the Kohler carburetor linkage diagram, follow adjustment tips, and consult the manufacturer’s guidelines. Align the throttle lever correctly, check for wear or damage, and listen for engine performance. This ensures optimal throttle performance.