GardenerHeaven.com is reader-supported. When you buy through links on our site, we may earn an affiliate commission.

Understanding power generation in lawn mowers is crucial for any lawn care enthusiast. In this section, we will delve into the defining components of lawn mowers and why it is essential to comprehend how power is generated within these machines. Let’s explore how this knowledge can help optimize lawn mower performance and ensure efficient operation.

Defining lawn mowers and their components

Photo Credits: Gardenerheaven.Com by Ryan Brown

Lawn mowers are machines for keeping outdoor grass and vegetation in shape. They usually include a cutting deck, engine, wheels, handles, and a grass collection bag. All these components work together to power and guide the mower.

The cutting deck houses the blades which cut the grass. It is made of strong materials such as steel or aluminum. The engine drives the blades and moves the mower. Wheels make it easy to maneuver, while handles give you a comfortable grip to control the mower.

The grass collection bag collects the cut grass for disposal or composting. Some mowers have added functions such as mulching, adjustable cutting heights, and self-propulsion systems.

It is important to understand the components of a mower. Having this knowledge helps you identify and fix any issues.

Power generation is also essential for mowers. This powers electrical systems like headlights, and charges batteries. To keep the mower running well, you should prioritize maintenance.

Alternators turn mechanical energy from the engine into electrical energy. They are particularly important in riding lawn mowers. Regular maintenance, such as charging the battery, inspecting connections, and cleaning debris, can improve performance and lifespan. Professional inspections and maintenance are also recommended.

Understanding power generation is key to keeping mowers running. Regular testing and troubleshooting can prevent further damage and costly repairs. Knowledge is the spark that keeps the blades turning.

Importance of understanding power generation in mowers

Gaining knowledge of power generation in lawnmowers is key for owners and operators. Power from these machines runs components and electrical systems. This includes charging the battery, powering lights, and powering the mower’s engine. Not understanding how power works in mowers can make it difficult to troubleshoot, maintain performance, and prolong life.

Knowing power generation in lawnmowers helps users make informed decisions. They can understand the generators and alternators in the engines. This helps them inspect belts and wiring, and replace worn-out parts. It also assists in troubleshooting any issues with the electrical systems.

Grasping power generation concepts allows for better communication between users and professionals. People can better describe any issues they have when seeking help. This lets technicians or mechanics diagnose and provide solutions based on their understanding of power generation.

Overall, understanding power generation in lawnmowers enables users to take care of their machines better. It also helps them interact better when seeking maintenance services.

Types of articles regarding lawn mowers

Photo Credits: Gardenerheaven.Com by Juan Roberts

Discover a wide range of article types that delve into the world of lawn mowers. From informative listicles to practical how-to guides, news articles to thought-provoking opinion pieces, feature articles to detailed comparisons, and honest reviews, each sub-section offers a unique perspective on mower-related topics. Get ready to explore the popularity, structure, updates, analysis, depth, evaluation, and assessment that these articles bring to the table. Let’s dive into the diverse articles surrounding the fascinating world of lawn mowers.

Listicles – Explaining the popularity and format of listicles in relation to lawn mowers

Listicles have become popular for conveying information about lawn mowers. They provide key points or tips in a concise and organized way. Reading listicles is time-efficient.

They offer maintenance tips, buying guides and troubleshooting advice. Bullet points and numbered lists make it easier to absorb and remember the information. Visuals, such as images and infographics, enhance understanding.

Listicles break down complex topics into smaller chunks. They provide an engaging experience by presenting content in an organized manner. It’s a valuable resource for anyone seeking specific mower-related information.

How-to Guides – Detailing the structure and purpose of how-to guides for mower maintenance

How-to Guides for mower maintenance are a must-have for anyone who wants to keep their mower in top condition. They provide detailed instructions and step-by-step procedures to help users care for their mower.

Here are some steps to follow when using these guides:

- Pre-check the blades, filters, belts, and other components to spot any issues.

- Gather the necessary tools and supplies, such as wrenches, lubricants, cleaning solutions, and replacement parts.

- Then, follow the guide’s instructions to complete the maintenance tasks, such as changing the oil or replacing the spark plug.

- Additionally, the guide will give tips for ongoing maintenance and general care.

Experienced users can use the guide for a refresher or to stay up-to-date with best practices. With these guides, individuals can confidently keep their mower in tip-top shape!

News Articles – Discussing the role of news articles in providing updates on mower technology and industry events

News articles are essential for lawn mower users who want to stay informed. They offer insight into new features, improvements, and innovations in mower design and functionality. Also, news articles highlight important industry events like trade shows, conferences, and exhibitions. Thus, they help users stay up-to-date on the latest trends and advancements in mower technology.

Furthermore, news articles go beyond presenting facts. They analyze the impact of new updates on the lawn care industry and provide expert opinions. This way, users can make informed decisions when buying a mower or considering upgrades.

News articles also inspire professionals and enthusiasts in the lawn care industry. They facilitate discussions on topics related to mower technology, encouraging innovation within the industry.

It was revealed that push mowers often lack alternators due to their manual operation. Riding lawn mowers, zero-turn mowers, and lawn tractors, however, are equipped with alternators. These alternators convert mechanical energy from the engine into electrical energy. This keeps the battery charged and the various electrical components of the mower working effectively.

Alternators enhance the convenience of riding lawn mowers, zero-turn mowers, and lawn tractors by powering lights, ignition systems, starter motors, and other accessories. To get the most out of these machines, proper maintenance and periodic inspections of the alternators are necessary.

Opinion pieces provide another dimension to the discussion of mower technology and industry events. By sharing personal thoughts on the subject, they add value to the conversation.

Opinion Pieces – Exploring the value of opinion articles in analyzing and discussing mower-related issues

Opinion articles are key to analyzing and discussing lawn mower issues. They provide more than just facts, giving readers a deeper understanding through personal stories, expert opinions, and individual perspectives. These pieces evaluate mower design, performance, environmental impact, maintenance, and user experience. They also address the larger social and environmental implications of using mowers.

Opinion articles offer a mix of subjective insights and objective information. They create conversations between experts and enthusiasts. They inspire thought and challenge traditional ideas about lawn mower use. They help readers make informed decisions and contribute to dialogue about the future of lawn care.

Feature Articles – Highlighting the depth and comprehensive coverage of feature articles on specific mower topics

Feature articles offer a deep dive into lawn mower topics. They provide a wealth of info in an easy-to-follow structure. Visuals like pictures, diagrams, and graphs help readers understand the topic better.

Experts offer their knowledge and insights in these articles. Interviews, case studies, and examples bring practical applications to life. The diverse perspectives give readers a more holistic understanding of the subject.

The articles also explore advancements in mower technology. They discuss how this can affect performance, efficiency, and user experience. This forward-looking approach keeps readers up-to-date on the latest industry developments.

Overall, feature articles provide comprehensive coverage of lawn mower topics. They are valuable resources for professionals, enthusiasts, and those buying a new mower.

Comparison Articles – Describing the purpose and format of comparison articles in evaluating mower options

Comparing lawn mowers is essential when selecting the right one. Comparison articles offer readers a thorough insight into various mower models, their features, specs, and performance. Comparing side-by-side enables consumers to make a well-informed decision that meets their particular needs and preferences.

For easy comparison, these articles often use tables. This provides a quick visual reference to examine engine power, cutting width, fuel type, and more. Tables allow readers to quickly assess advantages and disadvantages.

Apart from basic specs, comparison articles may also discuss unique selling points or innovations of certain models. Examples are self-propulsion systems or advanced cutting tech. These articles help readers pick a mower that suits their requirements.

Take a homeowner looking to upgrade his old push mower to a riding lawn mower. He came across a comparison article that listed key features and specs of different brands and models. This article helped him understand differences in terms of cutting efficiency, maneuverability, and ease of use. Armed with this knowledge, he chose a mower that met his needs and budget. Without this article, it would have been hard for him to assess the many options.

Reviews – Explaining the role of reviews in assessing the performance and value of different mower models

Reviews serve a vital role when it comes to analyzing the effectiveness and worth of different mower models. They can assess various aspects, such as cutting capability, durability, and features. Reviews give consumers helpful insights to make informed decisions from the opinions of other users or experts.

They check the performance of the mowers based on their cutting ability, such as maneuverability and accuracy. Plus, they review the value of the mowers by taking into account aspects like durability, construction quality, and durability. Reviews also show the key features of the mowers, like adjustable cutting heights, mulching capabilities, and self-propelling features.

Moreover, reviews often contain details about the user experience with mower models that are not available elsewhere. These details may include how easy it is to use, maintenance requirements, noise levels during operation, and even customer support experiences. Such data can be invaluable for potential buyers in deciding which mower model is right for them.

Are you ready to become an expert on lawn mower alternators? Let’s dive into the latest data!

Latest data on lawn mower alternators

Photo Credits: Gardenerheaven.Com by Gerald Green

Discover the latest data on lawn mower alternators and gain insights into their definition, function, and presence in various types of mowers. Uncover the distinctions between alternators and generators, and explore how alternators play a role in riding lawn mowers, zero-turn mowers, and lawn tractors. Learn why push mowers lack alternators due to their manual operation and dive into the appearance, location, and working principle of alternators in mower engines.

Definition and function of alternators in power generation

Alternators are an essential part of power generation in lawn mowers. They convert mechanical energy into electricity. This is for machines like riding lawn mowers, zero-turn mowers, and lawn tractors. You find them in the engine and they use the rotational motion of the crankshaft for power.

Generators and alternators both produce electricity, but they work differently. Alternators use electromagnetic induction to create AC. Generators use commutators and brushes to make DC. Alternators are more efficient and steady.

You need to maintain the alternator for the best performance in your mower. It’s not just for charging the battery, but also for powering lights, ignition systems, and other extras. Regularly charge the battery as the manufacturer says and follow tips for maintenance.

Plus, you should have it checked out from time to time. You can spot any issues or potential failures that way. Don’t forget to look at other pieces too, like the battery and wiring.

If the alternator isn’t working, you might get a dead battery, dim lights, or difficulty starting the engine. Test it with a multi-tester and watch the headlights when the mower is running. That way you can fix the problem.

A recent study suggests proper alternator maintenance and testing are key for optimal performance and long life in lawn mowers. Understanding alternators helps you decide how to maintain your machine and troubleshoot any issues.

Difference between alternators and generators

Alternators and generators both convert mechanical energy into electrical energy. Yet, their design and operation differ. An alternator utilizes a rotating magnetic field and stationary windings to produce alternating current (AC). On the other hand, a generator uses a fixed magnetic field and rotating windings to create direct current (DC). Here is a summary of the differences between them:

| Alternators | Generators | |

|---|---|---|

| 1. Design | Stationary windings and a rotating magnetic field | Rotating windings and a fixed magnetic field |

| 2. Current Type | Alternating current (AC) | Direct current (DC) |

| 3. Output Voltage Regulation | Built-in voltage regulation | Requires external devices or regulators for voltage regulation |

| 4. Efficiency | Generally higher | Might have slightly lower efficiency |

| 5. Maintenance Requirements | Less maintenance | More frequent maintenance |

Modern lawn mowers often utilize alternators, due to improved efficiency, voltage regulation, and less maintenance, compared to generators. Being aware of these distinctions helps people make informed decisions when selecting power generation components.

Presence of alternators in riding lawn mowers, zero-turn mowers, and lawn tractors

Alternators are vital to riding lawn mowers, zero-turn mowers, and lawn tractors. They generate energy for the battery and electrical components. Such components include headlights, ignition systems, electric starters, and more.

Push mowers don’t have alternators due to their manual operation. However, riding lawn mowers, zero-turn mowers, and lawn tractors need them! Alternators convert mechanical energy into electrical energy, charging the battery and powering various components. This helps users run their mowers well with no issues.

Absence of alternators in push mowers due to manual operation

Push mowers don’t feature alternators due to their manual setup. Instead of machinery to generate power, the user has to provide the necessary force. This means there’s no need for an alternator to create electrical energy for charging the battery or powering electrical systems.

The lack of alternators is connected to the push mower’s design and purpose. They’re often used for small lawns or spaces where maneuverability matters. The operator must push the mower and control the cutting height and direction. Because of this, an alternator isn’t needed.

On the other hand, other types of mowers like riding lawn mowers, zero-turn mowers, and lawn tractors require alternators. These machines have larger cutting decks and more powerful engines that need electricity for components like lights, gauges, and attachments. Alternators charge the battery and power these electrical systems.

To keep push mowers running optimally, regular maintenance is a must. Blades should be inspected and cleaned, and moving parts such as wheels and handles should be lubricated. Plus, debris will need to be cleared away to prevent any damage.

Though push mowers don’t need the same level of maintenance as those with alternators, users still need to follow manufacturer guidelines. This includes checking spark plugs, replacing air filters, and using quality fuel.

By understanding why push mowers lack alternators and how to maintain them, users can make sure their manual mowers operate efficiently for many years. Even though push mowers don’t offer the same convenience as those with alternators, they’re still a popular choice for small lawns or areas that need more maneuverability.

Trying to spot an alternator in a mower engine is like trying to find a unicorn in a crowded pasture.

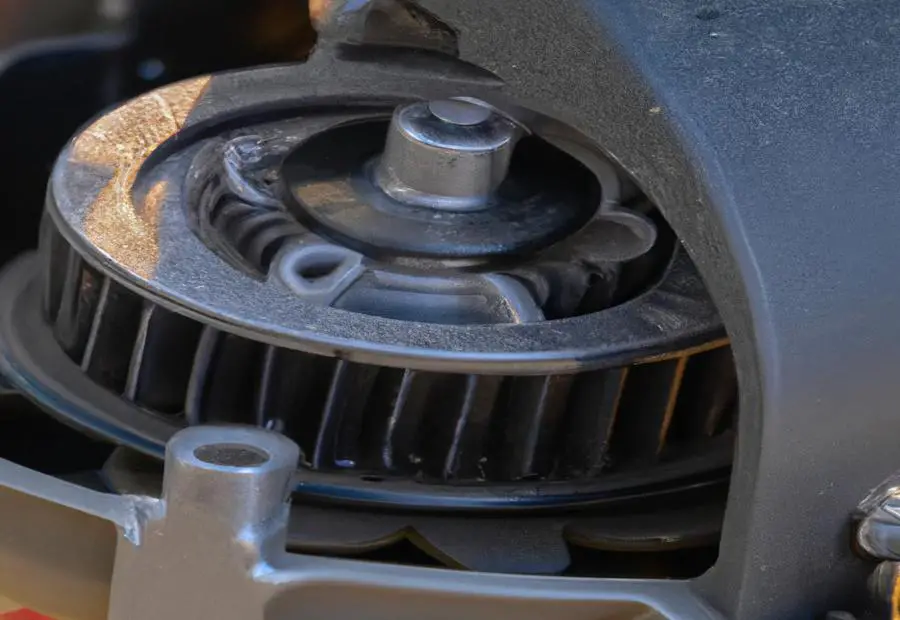

Description of alternator appearance and location in mower engines

Alternators in mower engines have a unique look. They’re strategically placed to generate the most power. These devices convert mechanical energy into electrical energy. They’re usually compact and found in the engine compartment. Alternators are connected to the engine by a belt and pulley system. This allows them to spin with the engine, creating electricity with minimal resistance and maximum output.

Components that make up an alternator include a rotor, stator, and diode bridge assembly. The rotor is made of wire that produces a magnetic field when an electrical current passes through. The stator remains stationary and has more wire windings. As the rotor spins in the stator’s magnetic field, the stator’s windings generate electricity. This converts mechanical energy from the engine into electrical energy.

Alternators are usually near the battery and starter motor. In some mower models, the alternator is part of a larger assembly known as the charging system or charging unit. This includes voltage regulators, rectifiers, and other components to regulate and distribute electric current.

Push mowers usually don’t have alternators. But riding mowers, zero-turn mowers, and lawn tractors often do. They use alternators for lighting systems, dashboards, attachments, and other electronics. Like a wizard with a sparkly wand, alternators work their magic, converting mechanical energy to electricity.

Working principle of alternators and their mechanism of converting mechanical energy into electrical energy

Alternators are critical for the power generation of lawn mowers. They convert mechanical energy into electrical energy. Knowing the workings of alternators is key for a good performance and long life.

The working involves various processes. The engine’s rotation drives a belt that is connected to a pulley on the alternator shaft. This spins the alternator rotor within its stator windings, creating an alternating magnetic field. This field induces an alternating current (AC) in the stator windings.

The AC is transformed into direct current (DC) with a rectifier assembly. This assembly has diodes that let current pass in one direction. The DC then charges the battery and powers various electrical systems, like lights, the ignition system and other accessories.

Alternators are usually found in riding lawn mowers, zero-turn mowers and lawn tractors, but not in push mowers. They have a distinct look and are located near or on top of the engine. Maintenance, including charging the battery and checking the electrical systems is important.

To assess and troubleshoot any issues with alternators, consulting the manuals and following safety precautions is best. Testing can be done with headlights or a multi-tester to measure voltage output from the alternator. Interpreting the test results accurately can help identify potential problems with the charging system or battery.

Knowledge of the workings of alternators is essential for good performance and longevity. Regular maintenance and testing are necessary to ensure optimal performance in riding lawn mowers. Keep up with alternator maintenance for a mow-nificent performance!

Importance of alternator maintenance in riding lawn mowers

Photo Credits: Gardenerheaven.Com by James Adams

Proper alternator maintenance is essential for the performance and lifespan of riding lawn mowers. From charging the battery to powering electrical systems, this section sheds light on the importance of regular alternator maintenance. Discover expert tips and professional inspections that can ensure optimal alternator functioning, allowing your mower to operate at its best and saving you from potential power generation issues in the long run.

Charging the battery and powering electrical systems

- Check the battery. Look for any damage or corrosion. Make sure the terminals are clean and connected.

- Connect charger. Link a battery charger to an outlet. Connect the red cable to the positive terminal and black cable to the negative.

- Set charging mode. Select the suitable charging mode based on the battery type installed in your mower. Follow manufacturer instructions.

- Begin charging. Turn on the charger and let it charge the battery. Monitor the process to avoid overcharging.

- Test voltage. Use a multimeter or voltmeter to check the voltage. It should be around 12 volts.

- Power electrical systems. Start the engine and test lights, ignition system and accessories. Make sure each component works.

Alternator maintenance is vital for your mower’s performance and lifespan. Inspect it regularly and get professional maintenance for optimal functioning. Make sure to take the proper steps to charge the battery and power the electric systems for hassle-free mowing and improved performance.

Tips for proper alternator maintenance to ensure mower performance and lifespan

To get the best performance and longest lifespan out of your mower, you need to maintain the alternator properly. It’s important because it charges the battery and powers the electrical systems. Neglecting maintenance can reduce the performance and damage the machine.

Follow this 4-step guide:

- Check it regularly for any signs of wear or damage. Look for loose wires, corrosion on terminals, etc.

- Keep it clean from dirt, debris, and other contaminants. Use compressed air or a soft brush.

- Tighten the connections between the alternator, battery, and electrical system components.

- Some alternators need lubricant. Follow the manufacturer’s instructions.

By following these steps, you will get better performance and a longer lifespan. Professional inspections should also be done periodically. Mechanics can check belts, wiring connections, voltage regulators, and brushes. This will help identify any issues and keep power generation at its best.

Push mowers don’t have alternators. But for riding lawn mowers, zero-turn mowers, and lawn tractors, keeping the alternator in top condition is essential.

Professional inspections and periodic maintenance for optimal alternator functioning

Regular inspections by trained professionals are essential for the optimal functioning of alternators in lawn mowers. They check the wiring, connections, and voltage output. Plus, periodic maintenance like cleaning, replacing brushes/bearings, and adjusting belt tension can maximize its lifespan and performance.

It’s also important to stick to manufacturer guidelines for inspection intervals and maintenance tasks. This helps to ensure proper care and more efficient power generation. Consulting a qualified professional during servicing is recommended to identify any issues or potential problems.

Troubleshooting the charging system, battery, and alternator of a small engine can be frustrating without all the pieces of the puzzle.

Testing and troubleshooting small engine charging system, battery, and alternator

Photo Credits: Gardenerheaven.Com by Stephen Rodriguez

Discover the key aspects of testing and troubleshooting small engine charging systems, batteries, and alternators in lawn mowers. Uncover common issues that arise with electrical charging systems and explore the importance of reading manuals and following safety precautions. Learn how to test the mower’s alternator using headlights or a multi-tester and gain insights into the steps involved in interpreting the results. Get ready to demystify power generation in mowers!

Common issues with electrical charging systems in lawn mowers

Lawn mowers can have various issues with their electrical charging systems. These include insufficient charging, intermittent charging, overcharging, and malfunctioning regulators. It’s essential to address these issues quickly to keep the system running properly.

You may need to consult your mower’s manual or get expert help if you experience specific issues. Also, regularly checking and maintaining your mower’s electrical charging system can prevent future problems. Don’t forget to read the manual and observe safety precautions – the last thing you want is a mower mishap that goes viral!

Importance of reading manuals and following safety precautions

Reading manuals is a must for safe mowing. They provide instructions on the mower’s features, controls, and maintenance. This knowledge prevents accidents and keeps the mower running smoothly. Safety precautions, like wearing protective gear and avoiding hazards, are outlined in the manual. This safeguards individuals, as well as the mower’s lifespan.

Operating lawn mowers safely is essential. They can cause injuries from blades, debris, or rollovers if not used right. So, the manufacturer’s manual must be read carefully before using. It has instructions on safety practices like wearing the right clothing and avoiding obstacles.

Other factors contribute to safety too. Regular maintenance according to the manual will reduce malfunctions. And users should be mindful of environmental considerations, like disposing fuel and oil properly.

Comprehending safety precautions protects individuals and improves mower performance and life.

Testing the alternator using headlights or a multi-tester

Unlock the alternator’s secrets and keep your mower juiced and ready to roll! Here’s a three-step guide on how to test it using headlights or a multi-tester:

- Start by taking safety precautions. Disconnect the spark plug wire and put on protective gear. Then, turn on the lawn mower’s headlights.

- Analyze the brightness of the headlights while mowing. If they are dim or flickering, it might indicate an issue with the alternator. A weak or faulty alternator may not be able to provide enough power to keep the headlights bright and consistent.

- To double-check, use a multi-tester to measure the alternator’s output voltage. Set it to DC voltage and connect the positive lead to the battery’s positive terminal and negative lead to its negative terminal. Start the engine and look at the tester. A healthy alternator should show 13-14 volts of output.

Remember to follow the manufacturer instructions specific to your lawn mower model. This will help you identify potential issues with power generation in lawn mowers and take the right steps for repairs.

Steps to test the alternator using a multi-tester and interpreting the results

To test an alternator using a multi-tester and interpret the results, follow these steps:

- Ensure the mower engine is off and the battery is disconnected. Always observe safety precautions.

- Connect the red lead of the multi-tester to the alternator’s output terminal or positive battery cable. Then attach the black lead of the tester to the negative battery post.

- Switch on the multi-tester and measure voltage. A working alternator should display readings between 13.8-14.4 volts DC while the engine runs.

- If the reading is below 13 volts, it indicates an undercharging alternator and may need inspection or repair. If the reading is over 15 volts, it suggests an overcharging problem that requires attention.

These steps provide a general guide but may differ according to the mower model or manufacturer’s guidelines. Check the mower’s manual or seek professional help for precise instructions suited to individual machines.

Testing an alternator using a multi-tester and interpreting the results correctly allows lawn mower owners to diagnose charging system issues and deal with them quickly. This ensures optimal performance of their equipment!

Conclusion

Photo Credits: Gardenerheaven.Com by James Gonzalez

In conclusion, understanding the role of alternators in lawn mowers is crucial. We’ll summarize the various articles and the latest data discussed, highlighting the importance of alternator maintenance and testing for optimal mower performance. Don’t overlook this essential component in your lawn care routine!

Emphasizing the importance of understanding alternators in lawn mowers

Comprehending the concept of alternators in lawn mowers is critical for their optimal performance and upkeep. They generate electrical power, allowing the battery to be charged and powering electrical systems. Knowing how they work and their importance in transforming mechanical energy into electrical energy helps increase mower efficiency and lifespan.

Regular maintenance and professional inspections are required to avoid issues and keep the mower running. This knowledge helps users troubleshoot small engine charging systems, batteries, and alternators. This awareness adds to the efficiency and longevity of the mower. Following proper maintenance tips and seeking professional inspections can maximize performance.

Also, understanding the difference between generators and alternators makes it easier to choose a lawn mower model that suits specific needs. Manual push mowers do not require power generation. Therefore, users of riding lawn mowers, zero-turn mowers, or lawn tractors need to be familiar with the appearance and location of an alternator in their engines. This helps identify any potential issues and facilitates troubleshooting.

Summarizing the types of articles and latest data discussed

To summarize the types of articles and data discussed about lawn mowers, a table can be created. It would consist of columns for each article type, with rows listing their format, purpose, and topics.

| Article Type | Format | Purpose | Topics |

|---|---|---|---|

| Feature Articles | Comprehensive analysis | Provide in-depth coverage | Detailed mower reviews, maintenance tips |

| News Articles | Updates and latest information | Keep readers informed of advancements | New mower models, industry trends |

Each type of article offers a unique perspective and depth in its coverage. For instance, feature articles provide comprehensive analysis, while news articles update readers on advancements.

To make the most out of these various articles, users should actively seek information relevant to their needs or interests. Reading comparative reviews can help buyers evaluate mower options. Regularly reading news articles keeps one updated on trends. Maintaining regular alternator maintenance ensures optimal power generation. Applying this information and recommended practices enhances one’s experience with lawn mowers.

Highlighting the significance of alternator maintenance and testing for optimal mower performance

Maintaining and testing a lawn mower’s alternator is important. Without maintenance, the alternator may not charge the battery or power electrical systems. This leads to decreased mower efficiency. Inspections and maintenance are recommended.

To check the alternator’s performance, use a multi-tester or headlight. Mower owners should take care of their alternators to get the best performance and avoid potential problems.

Some Facts About “Do Lawn Mowers Have Alternators? Understanding Power Generation in Mowers”:

- ✅ Alternators are generators that convert mechanical energy into electrical energy. (Source: Team Research)

- ✅ Riding lawn mowers have alternators, while push and walk-behind mowers do not. (Source: Team Research)

- ✅ Alternators charge the battery on a lawn mower and provide electricity to components such as electronic ignition, headlights, and clutches. (Source: Team Research)

- ✅ Lawn tractors also have alternators, which are located under the hood in the front of the mower. (Source: Team Research)

- ✅ Alternators work through electromagnetic induction, converting mechanical energy into electrical energy while the engine is running. (Source: Team Research)

FAQs about Do Lawn Mowers Have Alternators? Understanding Power Generation In Mowers

Do lawn mowers have alternators?

Answer: Yes, lawn mowers can have alternators, especially riding lawn mowers and lawn tractors. Alternators are responsible for generating electricity to power the various electrical components of the mower.

What type of lawn mowers have alternators?

Answer: Riding lawn mowers, zero-turn mowers, and lawn tractors commonly have alternators. These types of mowers require a continuous power supply to efficiently run their features and accessories.

How do alternators work in lawn mowers?

Answer: Lawn mower alternators work through electromagnetic induction. As the engine runs, a belt connects the engine’s crankshaft to the pulley of the alternator. With every revolution, a magnetic field is created within the alternator, generating currents that flow through the windings of the stator. This current is then converted from alternating current (AC) to direct current (DC) using a rectifier.

What are the signs of a faulty alternator in a lawn mower?

Answer: Signs of a faulty alternator in a lawn mower can include a battery that won’t hold a charge, onboard electronics not operating properly, and the headlights dimming when the engine is running. If the alternator is not functioning properly, it may need to be inspected and repaired by a qualified lawn mower mechanic.

Can I test the alternator in my lawn mower?

Answer: Yes, you can test the alternator in your lawn mower. One simple method is to turn on the headlights while the engine is running. If the lights dim, it means the alternator is working correctly. Alternatively, you can use a multi-tester to measure the voltage or current output of the alternator.

How do I maintain the alternator in my riding lawn mower?

Answer: Proper maintenance of the alternator is important for the longevity and performance of your riding lawn mower. Some maintenance tips include keeping the alternator clean, regularly checking the alternator belt for wear or damage, monitoring the health of the battery, and seeking professional inspections when needed. Regular maintenance will help ensure the proper functioning of the alternator and the electrical systems of your mower.